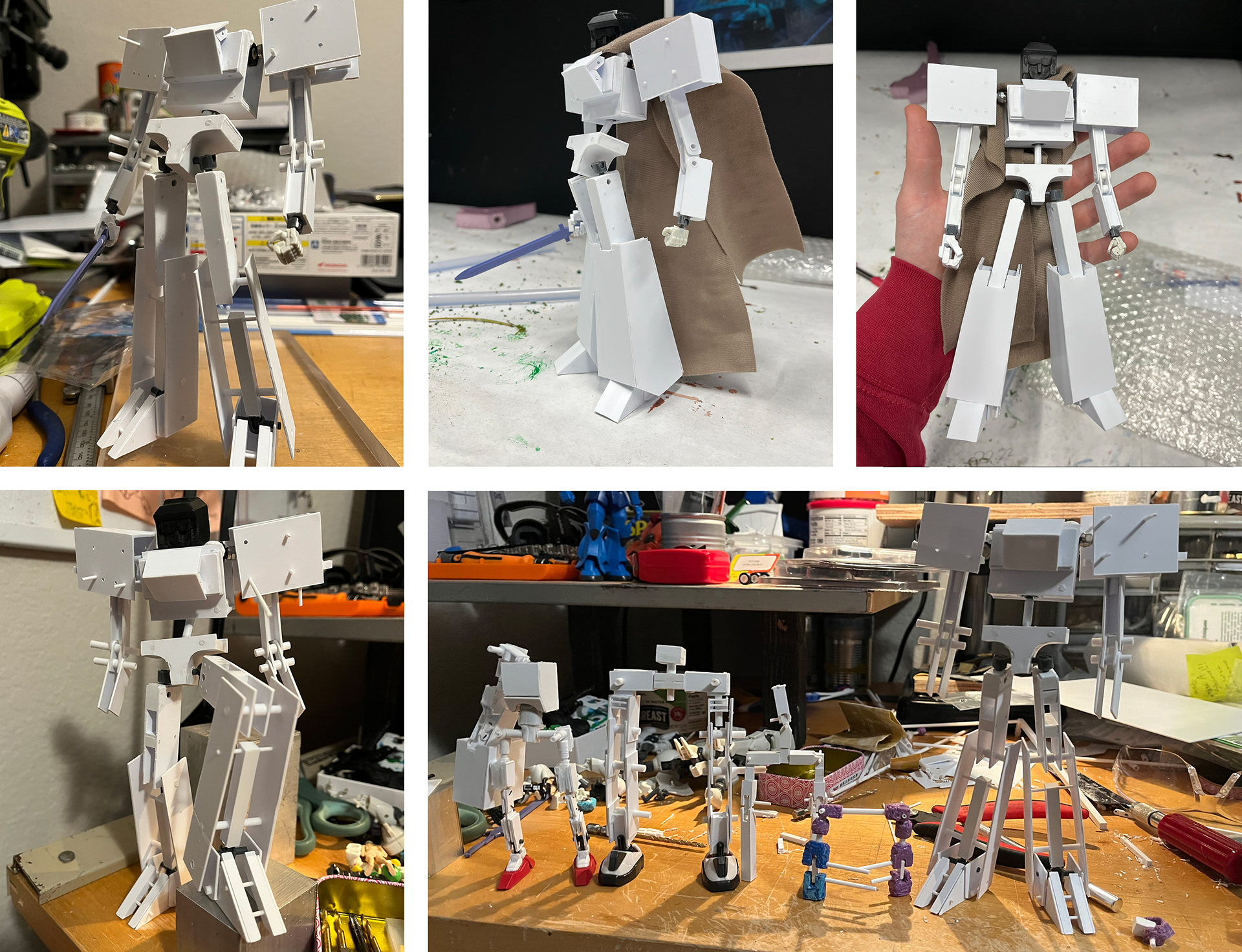

I design and prototype physical products with the mindset of an industrial designer and the hands-on execution of a fabrication lab. My work spans toy concepts, wearable modifications, mechanical parts, and live-action props—often blending digital design, VR sculpting, and rapid fabrication into iterative, testable objects.

While I’m not an engineer by degree, I approach product design with engineering-level complexity: breaking forms into manufacturable parts, designing for assembly and articulation, and testing fit, tolerance, and durability through physical iteration.

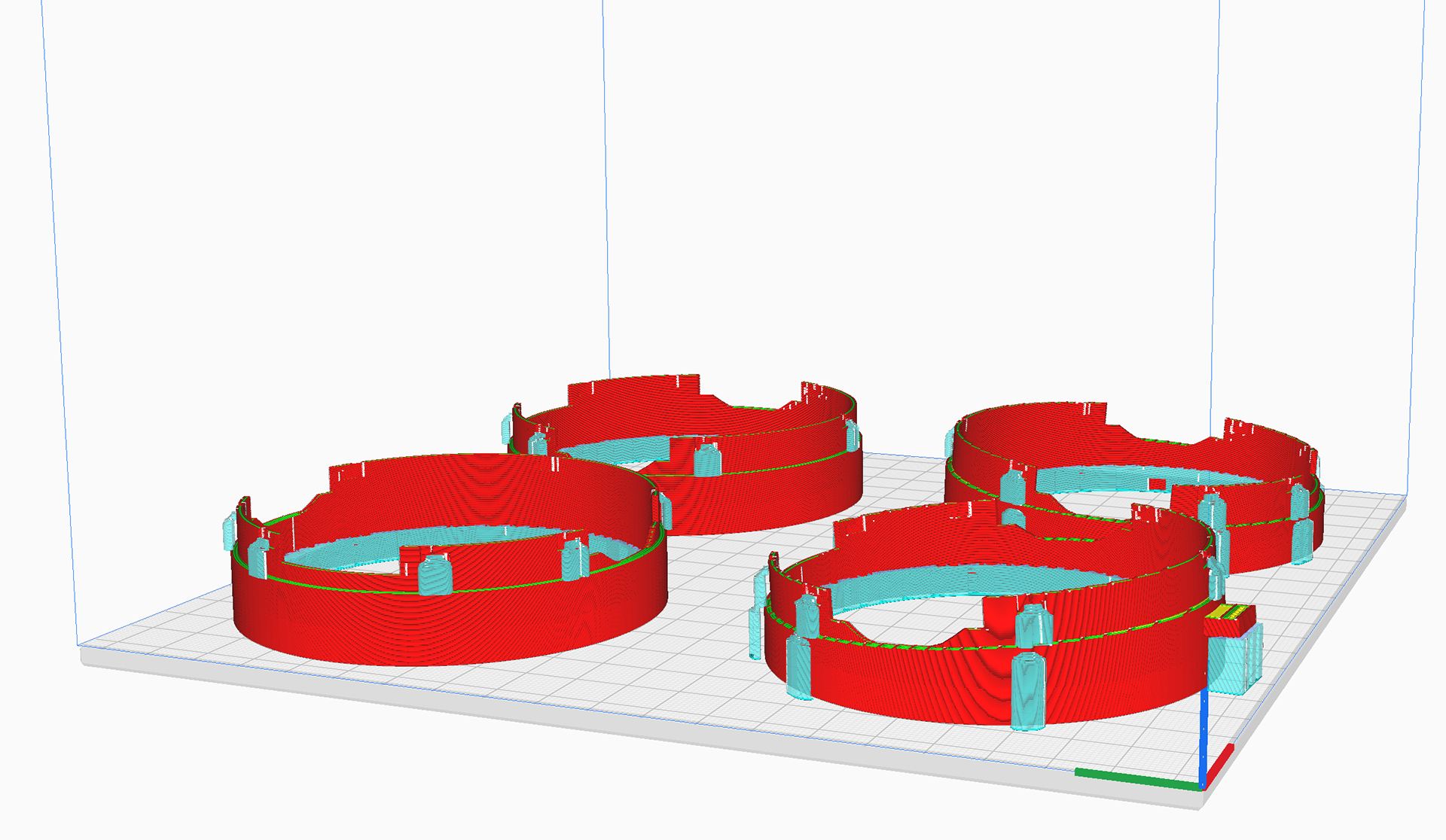

My process combines digital-first design with physical problem-solving:

• Concepting forms as functional objects, not just visual models

• Designing parts for modularity, articulation, and real-world constraints

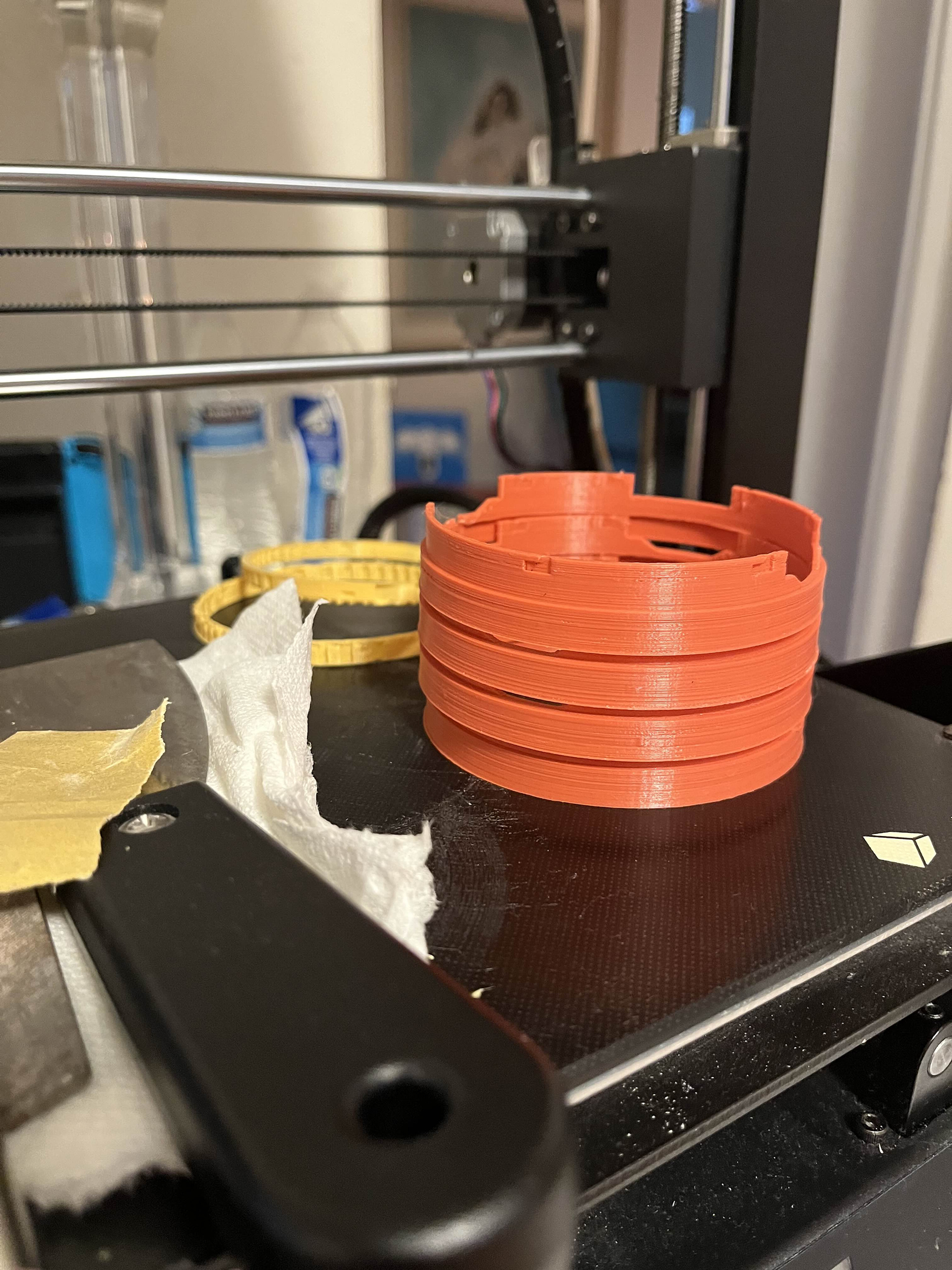

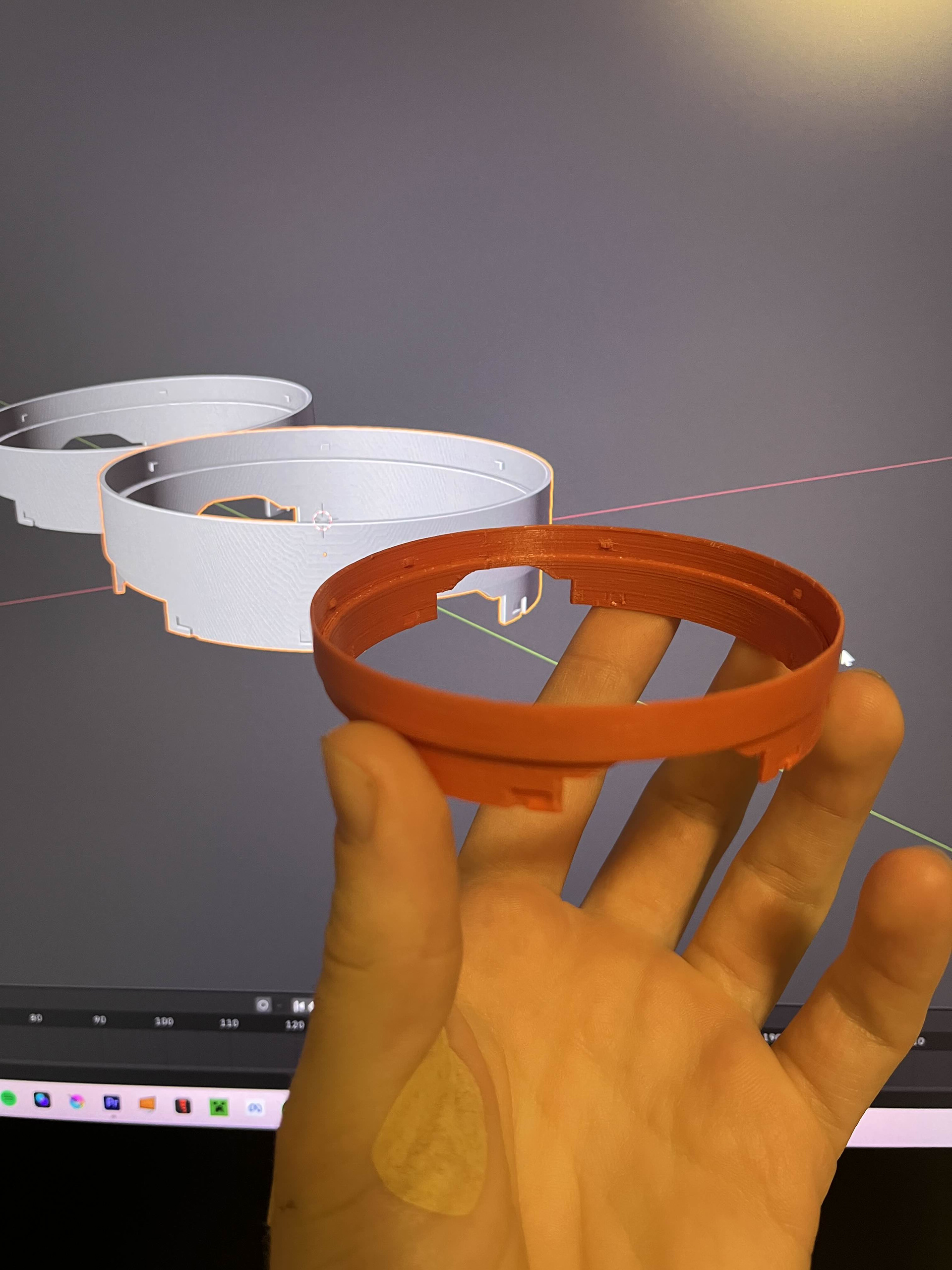

• Rapid iteration through 3D printing and hands-on testing

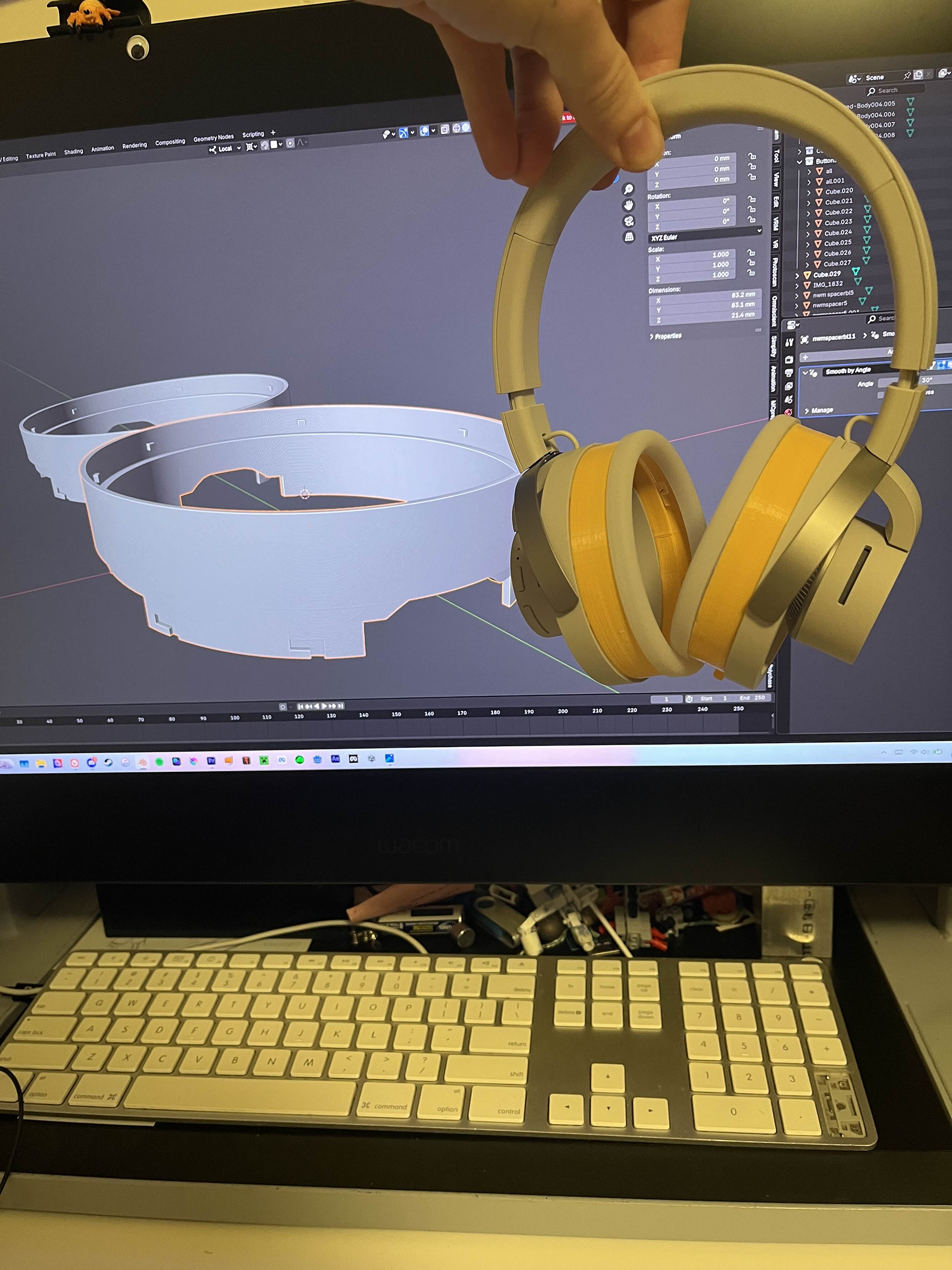

• Modifying and customizing existing products to explore new use cases

• Concepting forms as functional objects, not just visual models

• Designing parts for modularity, articulation, and real-world constraints

• Rapid iteration through 3D printing and hands-on testing

• Modifying and customizing existing products to explore new use cases

This workflow allows me to move quickly from idea to object—adjusting geometry, mechanisms, and ergonomics in response to real-world feedback.